As the weather warms up and flowers start to bloom, it’s the perfect time to enjoy some springtime activities. One fun and relaxing way to … Read more

Continue reading

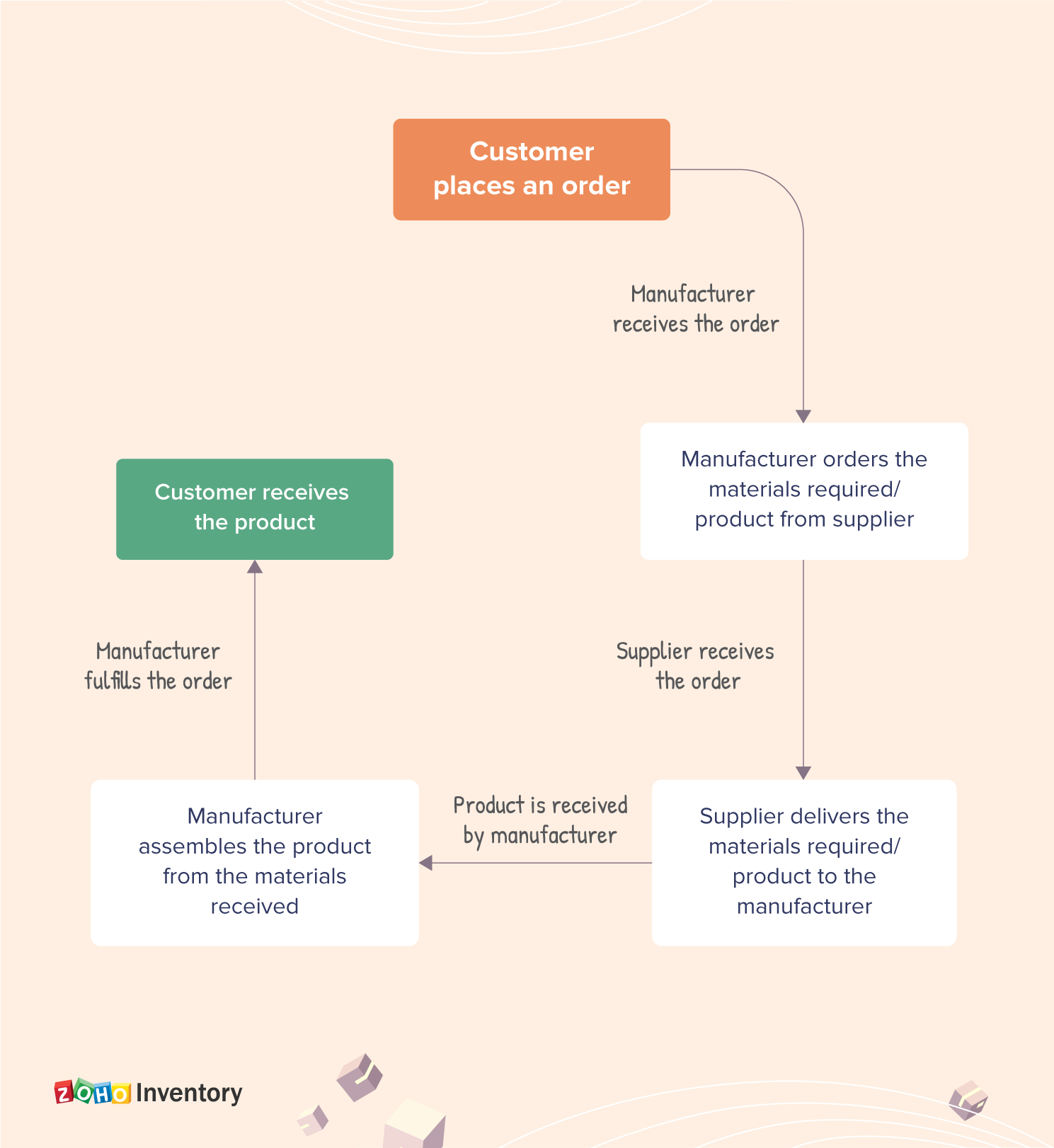

Just In Time inventory JIT is an inventory management method that focuses on keeping as little inventory on hand as possible Here s how it works Inventory is a valuable asset in many The Just in Time (JIT) style of inventory management – also sometimes referred to as the Toyota Production System (TPS) – is a strategy of managing inventory and/or production that links the ordering of raw materials to production scheduling. It differs from other strategies of inventory maintenance.

Just in Time JIT Inventory Management Explained JIT inventory ensures there is enough stock to produce only what you need when you need it The goal is to achieve high volume production with minimal inventory on hand and eliminate waste How Does Just in Time Inventory Management Work Just-in-time (JIT) is a management approach that is used to control the flow of inventory to and from a business in order to minimize inventory levels and to improve the efficiency of the manufacturing processes.

What Is Just In Time

Just in time or JIT is an inventory management method in which goods are received from suppliers only as they are needed The main objective of this method is to reduce inventory holding costs and increase inventory turnover Lean for logistics just in time training. what is just in time and how could brexit affect it osv what is just in time manufacturing jit supply chain india jobs.

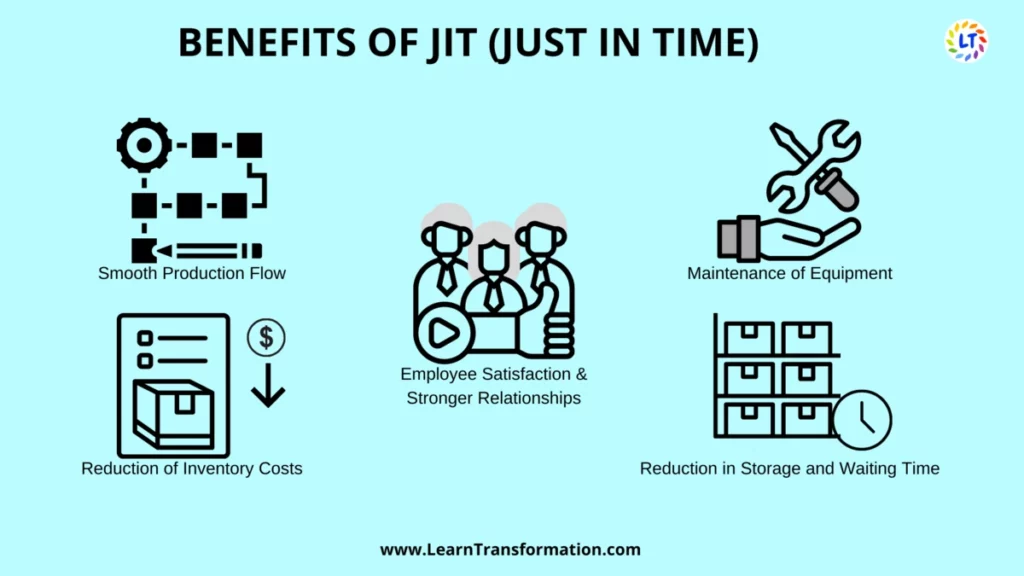

What Is Just In Time In Lean Management Learn Transformation

The Benefits Of Just in Time Inventory Management Kyinbridges

What is Just in Time JIT The Just in Time JIT concept is a manufacturing workflow method It s used to reduce flow times and costs within production systems and the distribution of materials A just-in-time system of manufacturing (= producing goods) is based on preventing waste by producing only the amount of goods needed at a particular time, and not paying to.

A just in time system of manufacturing producing goods is based on preventing waste by producing only the amount of goods needed at a particular time and not paying to Just in Time (JIT) is an efficiency-focused management philosophy that synchronizes a company’s material orders from suppliers directly with their production schedules. This approach, which thrived in post-war Japan and was honed by Toyota, minimizes inventory costs and reduces waste by ensuring materials arrive only as needed. .

As the weather warms up and flowers start to bloom, it’s the perfect time to enjoy some springtime activities. One fun and relaxing way to … Read more

Continue reading

Birds are fascinating creatures that capture our attention with their beautiful colors and unique songs. Whether you’re a bird enthusiast or just looking for a … Read more

Continue reading

Are you looking for some fun and creative activities for your kids? Why not try out some robot printable coloring pages! These coloring pages are … Read more

Continue reading

Valentine’s Day is just around the corner, and what better way to celebrate than with some fun and creative activities like coloring pages! Whether you’re … Read more

Continue reading

If you’re looking for a fun and creative way to relax and unwind, abstract coloring pages printable are a great option. These unique designs offer … Read more

Continue reading

If you’re looking for some fun and creative activities for your kids, why not try printing out some Mickey and Minnie Mouse printable coloring pages? … Read more

Continue reading

If you’re a cat lover like me, you’ll be thrilled to know that we have a fantastic collection of Cats Printable Coloring Pages for you … Read more

Continue reading

Are you looking for a fun and relaxing way to unwind after a long day? Why not try coloring! Printable coloring pages of animals for … Read more

Continue reading

If you’re a fan of Betty Boop and love to color, you’re in luck! We have a wide selection of Betty Boop printable coloring pages … Read more

Continue reading

If you’re looking for a fun and creative activity for your kids, why not try out some free printable coloring pages of scarecrows? These pages … Read more

Continue reading